Electrical Thermal Scans and Electrical Infrared Inspections in Cooper City, Davie, Pembroke Pines, Southwest Ranches, Weston FL

Don’t get left in the dark and pay twice as much for a repair. Catch it early and pay less with minimal down time.

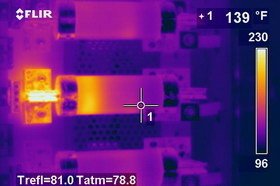

Electrical Infrared Inspections are an integral part of any Preventative Maintenance and Loss Control Program. Many problems in electrical systems are caused by abnormal heating associated with high resistance or excessive current flow. Infrared thermal scans allows us to see these invisible thermal patterns before damage or failure occurs. Infrared surveys are useful in any application where a temperature difference can be used to identify problem areas.

Electrical Infrared Scan FAQWhat appears to be good…

…is about to burn up!

$ave$ money

Heat is wa$ted power = wa$ted money

Saves energy = Saves money

Electrical infrared inspections locate problems typically not found during shutdowns. It also finds overloaded, loose, and corroded connections.

Some of the many benefits to having your equipment scanned are:

- Reduces costly downtime

- Saves time and money on emergency repairs

- Prevents equipment failures

- Identifies and prioritize areas needing preventative maintenance

- Improves electrical and mechanical efficiency

- Avoids disruption of services by using noninvasive technology

- Reduces emergency calls for maintenance crews

- Identifies fire hazards

What is an Infrared Thermal Scan?

What is an Infrared Thermal Scan?

Although not a substitute for a maintenance program, thermal imaging (infrared) is a valuable tool that can be done while the equipment is energized. If done safely and properly, an infrared inspection can identify loose bus connections before they result in a full or partial equipment outage. Maintenance can be scheduled to correct the identified issue. Having infrared viewing windows installed allows infrared inspections to be done quickly and safely.

Inspections with infrared thermal cameras are a non-contact noninvasive means of scanning and data collecting.

During a scan no equipment will need to be shut down. Which means no downtime for your equipment. Infrared imaging reveals electrical problems based on subtle temperature variations caused by loose connections, phase imbalance, circuit overloading and other “invisible” problems that can lead to equipment damage or breakdowns.

Electrical infrared inspections are an integral part of any preventative maintenance and loss control program.

Electrical infrared inspections are an integral part of any preventative maintenance and loss control program.

Utilizing thermal scanning on at least an annual basis for electrical and mechanical systems can improve the reliability of these systems and increase profitability.

Finding and fixing a poor electrical connection before a component fails can save you the much greater costs associated with manufacturing downtime, production losses, power outages, fires and catastrophic failures.

“Planned maintenance of plant and equipment that is designed to improve equipment life and avoid any unplanned maintenance activity.”

Temperature differences, even though small, can be serious, depending on the equipment, the load or voltage it is carrying, and the need for continuity of operation. Therefore, the ultimate decision to repair them must be made by the plant personnel. The problems found with infrared fall into two general categories: contact surface problems and overload imbalance problems.

An Overload or Imbalance problem is when heat is produced by high current flow and/or high resistance through a portion of the circuit or a phase of the circuit. These are generally associated with under size conductors, overload phase imbalances.

A Contact Surface problem is when heat is produced by current flow through a single point of electrical contact with high resistance.

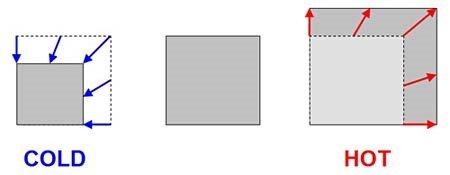

Thermal Expansion

Most materials expand as they are heated and contract if they are cooled. This is known as Thermal Expansion. Thus, their length is a function of temperature. If the length of an object is L and the temperature changes by a different amount dT, then the differential change in the length is dL is given by: dL=xL dT

Preventative Maintenance

- Helps to improve power quality

- Helps stop wasting energy due to heat loss.

- Reduces down time

- Increases safety

Our Service & Your Business

Our Service & Your Business

JPEG Electrical Services uses state-of-the-art instrumentation and testing procedures to identify any facet that may lead to your equipment’s deterioration. We can help you develop a short, intermediate and long term plan to correct or improve you overall systems’ safety reliability and performance.

If you would like more information on electrical thermal scans and electrical infrared inspections or any of the other eectrical services that we provide, please fill out the quote form and we will contact you shortly. If you would like to schedule a service call, please fill out the Request Service form or send us a text at 954-410-3995.